| The end result of all

this research and development is that Microsolar's exclusive technology

gives the highest temperatures and the most hot water. Making electricity

backup heaters obsolete.

Microsolar's hybrid double glazed panels 47 gals/213 ltrs 4.4m2 collector will reach 90°C (measured at showerhead) on clear blue sky sunny days in Kuala Lumpur, Malaysia which has an ambient air temperature 32°C. This is world record level performance for a solar water heater without pumps, no electricity (at all), no chemicals, no vacuum tubes. Most Conventional solar water heaters will not reach above 75°C. Microsolar has been awarded (one of four worldwide recipients) the prestigious Time Magazine's "Heroes of the Planet - Design", in their 5 April 1999 Time Magazine issue. |

|

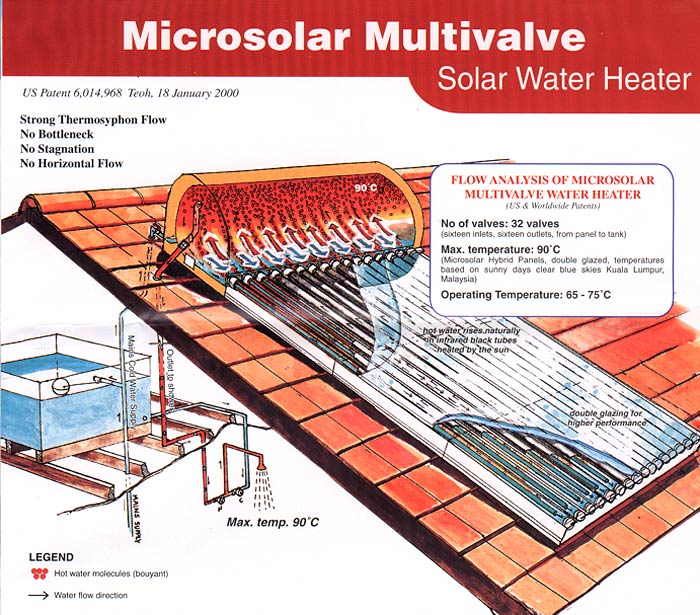

| WHY IS

MICROSOLAR'S MULTIVALVE DESIGN BETTER?

In Microsolar's Patented Multivalve Technology each heating tube (16 in all, 25mrn diameter) has its own dedicated inlet / outlet valve 25mm diameter directly to the hot water tank. They are not squeezed into a common manifold pipe, and there is no overall constriction of flow diameter, or bottleneck, in the thermosyphon flow. Microsolar's Multivalve is comparable to 16 lanes on a highway flowing smoothly, while conventional single feeder pipe systems can be compared to 16 traffic lanes squeezed into one single lane - a traffic jam results. Microsolar also does not have any horizontal flow in its thernaosyphon circuit, unlike conventional solar water heaters. All flow is straight up or down following the natural direction of convection flow, no stagnation, no hot spots. |

|

Microsolar uses the upwelling momentum of 16 streams of hot water from the 16 direct thermosyphon valves to inject hot water deep into the back of the hot water tank all across the length of the tank.

ACTIVE EXPULSION OF COLD WATER FROM TANK

The cold water is thus expelled from

the tank actively downwards directly through 16 valves into the bottom

of the panel. Conventional single feeder pipe systems cannot do this with

only one inlet valve.